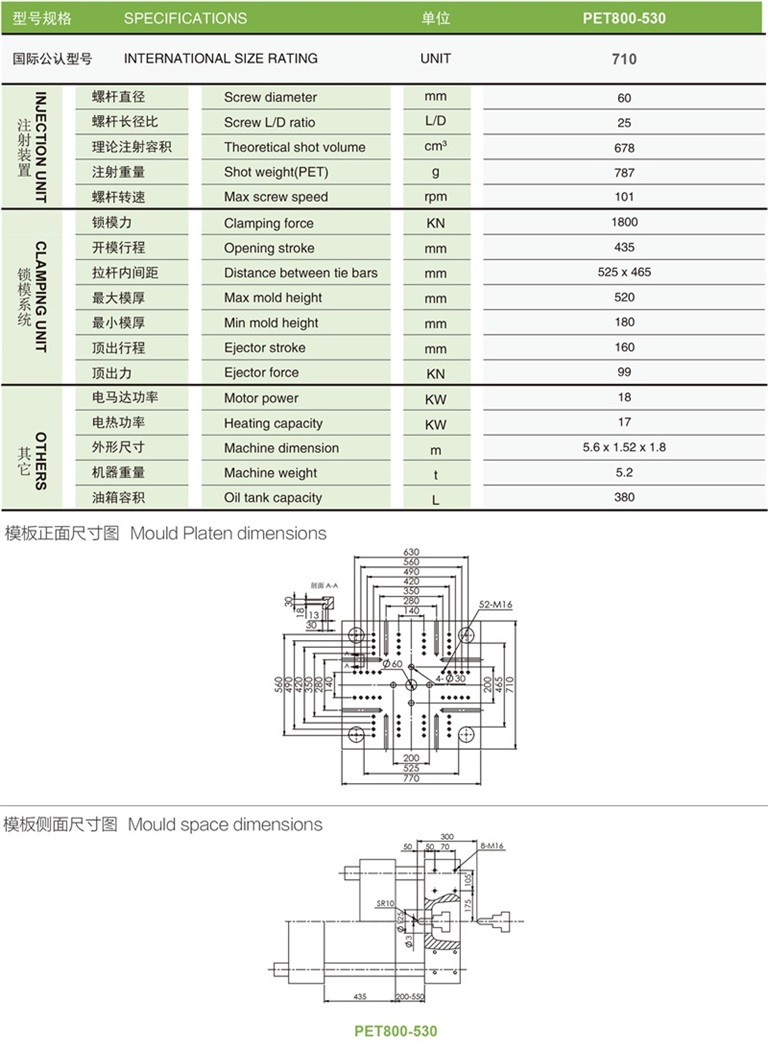

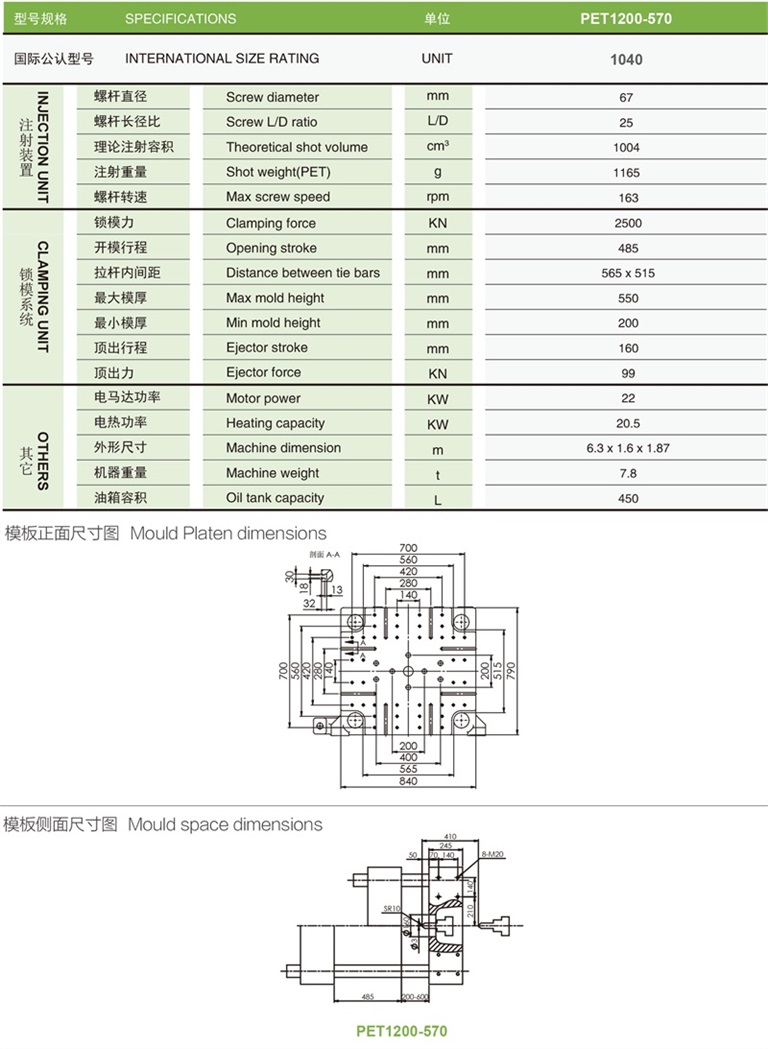

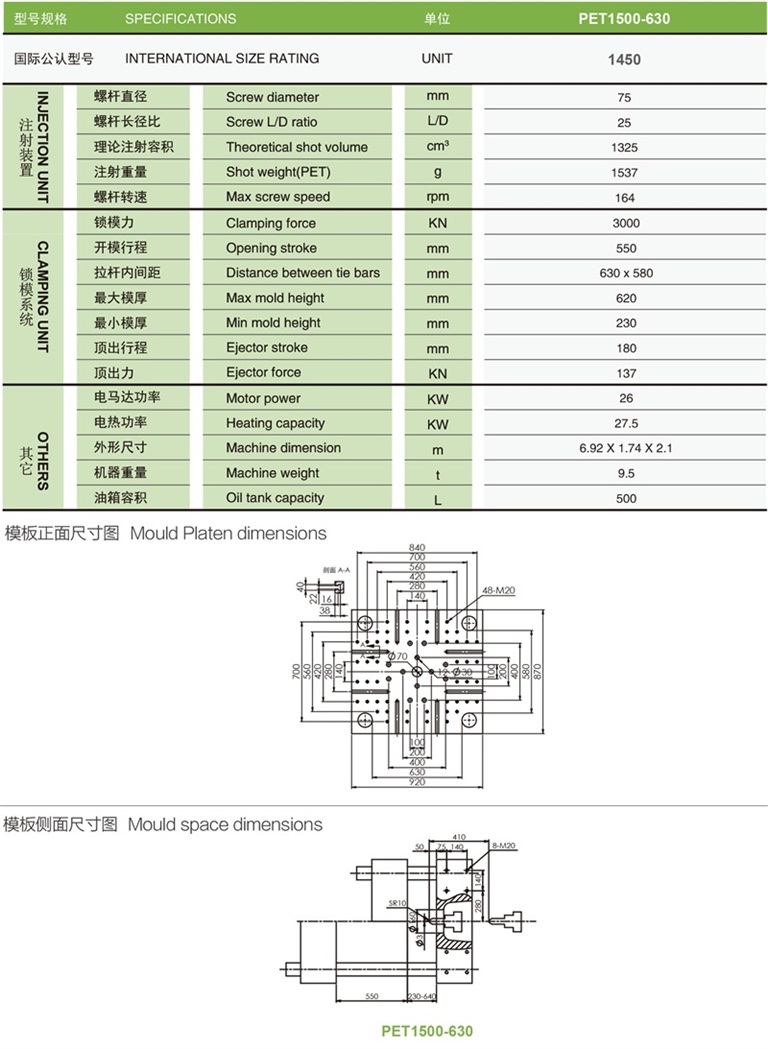

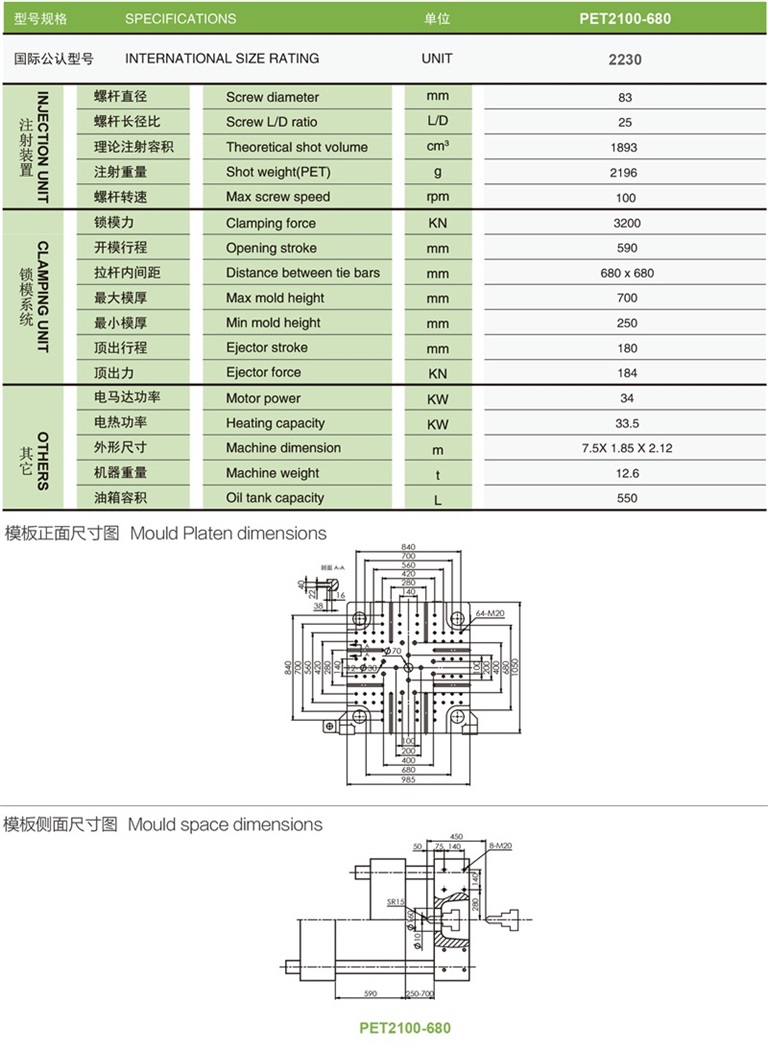

■ By the recognition of the market with large column spacing, and efficient to meet the PET preform mould size is larger, the practical needs of the CLAMPING force smaller industry characteristics.

■ Increase the power of the motor configuration 20% faster than conventional machines .

■ The shot weight increased by 40% compared witti the conventional machine, the melt cycle is shorter.

■ Increase the eject power and stroke distance are more than 30%, which is more suitable for multi cavity and deep cavity forming.

■ Adopting the servo proportional system, comparing with traditional system, it can save energy 30% to 60%, Also, can save water 30%.

■ The injection unit adopts the structure of double linear guide rail, so that the injection is faster, more accurate and more stable.

■ High rigidity T slot platen, more convenient to replace the mold needs.